Petrol tune-up vol.1: Injection cleaning

December 17, 2018

Solid lubricants: Graphite oil additive

December 17, 2018In our last article we compared MoS2, Teflon and graphite as solid lubricants. Now it’s time to talk about the cream of the crop: ceramic (boron nitride). Also called “white graphite”, the ceramic powder of hexagonal boron nitride is the best dry lubricant in the oil additive business. Keep reading to discover why.

Performance

When we talk about solid lubricants, we refer to materials capable of reducing friction between two surfaces. The main advantage of having them mixed in with our oil is that they significantly reduce wear while improving our oil’s durability.

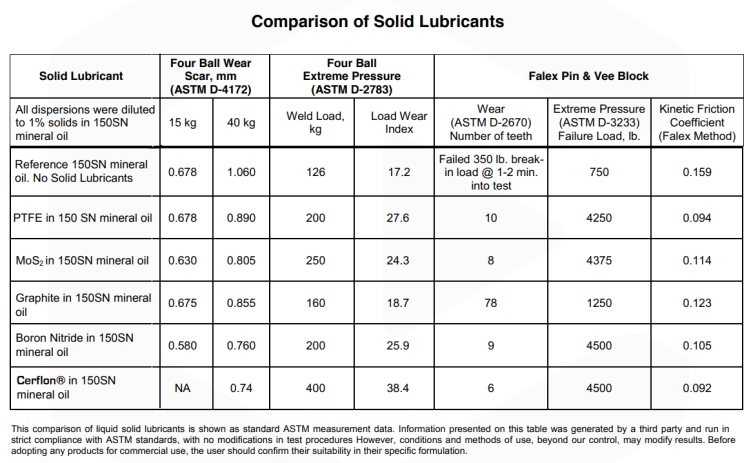

After analysing the other 3 additives (PTFE, MoS2 and graphite), we have probably already said everything about their differences and uses. On this occasion, we will let numbers speak for themselves.

Source: Cerflon site

As we descend in the table we see how each material generally improves on the results of the previous one. When we get to Boron Nitride, we notice that this lubricant outperforms the previous additives in every aspect. Ceramic easily wins the wear scars (D-4172) and extreme pressure (D-3233) tests. Moreover, it gets close to both PTFE and MoS2 in the extreme pressure (D-2670) and kinetic friction (Falex) tests.

However as you can see, the winner is Cerflon, mentioned in the PTFE article, with an overall excellence.

However, as always, we must use perspective. As we have pointed out in our Technology section, the problem with Cerflon, and PTFE, is their operational temperature range. While ceramic can withstand more than 1.000ºC, Cerflon maxes out at 300ºC.

Ceramic oil additive in Xenum

As with graphite, the potential of this additive made us believe that the perfect oil hadn’t been designed yet. That is how the VRX range was created.

If you are about to change your oil, our recommendation is to go for the VRX ceramic oil range. Currently we have 5W30, 5W40 and an exclusive 7.5W40.

On the other hand, if you have recently changed your oil, we would recommend our top-of-the-range additive, VRX 500. This additive contains a higher concentration of hBN particles and is available in a larger volume than its relative, the CE300.

It’s also worth mentioning our VRX 500 has a -41% friction reduction, according to a leading certification company. The components present in VRX 500 are in all the VRX range, so they show similar results.

Stay tuned!

Don’t forget to subscribe to our newsletter to receive news regularly discussing our products.

The post Solid lubricants: Ceramic additive (hBN) appeared first on Xenum Power of Technology.